|

|

Product Descriptions:

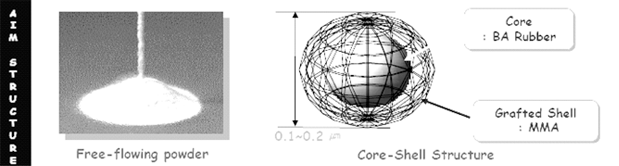

EVEREN Acrylic impact modifier E301 developed by our company is an acrylic copolymer with a core-shell structure, it is mainly used to improve the impact-strength and weatherability of PVC finished products with Hi-impact needs. it is recommended for applications such as PVC profile, PVC fencing and PVC siding etc. where good outdoor weathering and low-temperature impact resistance are critical properties.

Technical standards of pure E301:

|

Item |

Unit |

Technical Standard |

Executive Standard |

|

Appearance |

--- |

White free-flow powder |

--- |

|

Volatile content |

% |

≤1.50 |

GB/T2914 |

|

Bulk density |

g/cm3 |

0.5-0.6 |

GB/T1636 |

|

Sieve residue(30mesh) |

% |

≤2.00 |

GB/T2916 |

|

Foreign particle |

Cm2(10*10) |

≤20.00 |

GB/T9348 |

Comparison data of fusion/Mechanical properties:

|

|

E301 |

Fm-21 |

Km-355 |

Im-808A |

|

Fusion time(S) |

168 |

160 |

174 |

178 |

|

Highest torque(Nm) |

36.0 |

35.6 |

35.8 |

35.0 |

|

Constant torque(Nm) |

23.5 |

23.5 |

23.6 |

23.4 |

|

Temp @constant Torque. ℃ |

185 |

184 |

185 |

183 |

|

Izod Impact strength(23℃ condition) |

18.6 |

17.4 |

18.1 |

18.9 |

|

Izod Impact strength(-10℃ condition) |

11.3 |

11.0 |

11.2 |

11.5 |

|

Tensile strength |

397 |

393 |

404 |

409 |

|

Elongation at break |

176 |

160 |

172 |

177 |

Products advantages:

1. uniform particle size and low dust.

2. Excellent compatibility with PVC resin

3. Excellent long-term weather-resistance

4. better dimensional stability and thermal stability

5. higher impact-resistance.

6.Execellent dispersity and no caking

Packaging and Storage:

25kg/bag with PP bag and PE inner bag or 550kg/sack PP bag with PE liner

It should be stored in cool and dry surroundings with shelf life of two years, it can be used if qualified by inspection after shelf life.

Applications:

E301 is recommended for applications such as PVC window profile , PVC door and fencing etc. where good outdoor weathering and low-temperature impact resistance are critical.

Recommended using dosage:4.0-6.0kg per 100kg PVC resin.